Factory Cheap Hot Disc Wood Chipper - waste wood pellet production line – Zhangsheng

Factory Cheap Hot Disc Wood Chipper - waste wood pellet production line – Zhangsheng Detail:

Wood pellets have high calorific value, low cost, compact size, convenient transportation and no pollution. With the increasing shortage of coal, oil and other energy sources, the market demand for wood pellets is increasing and the profits are considerable.

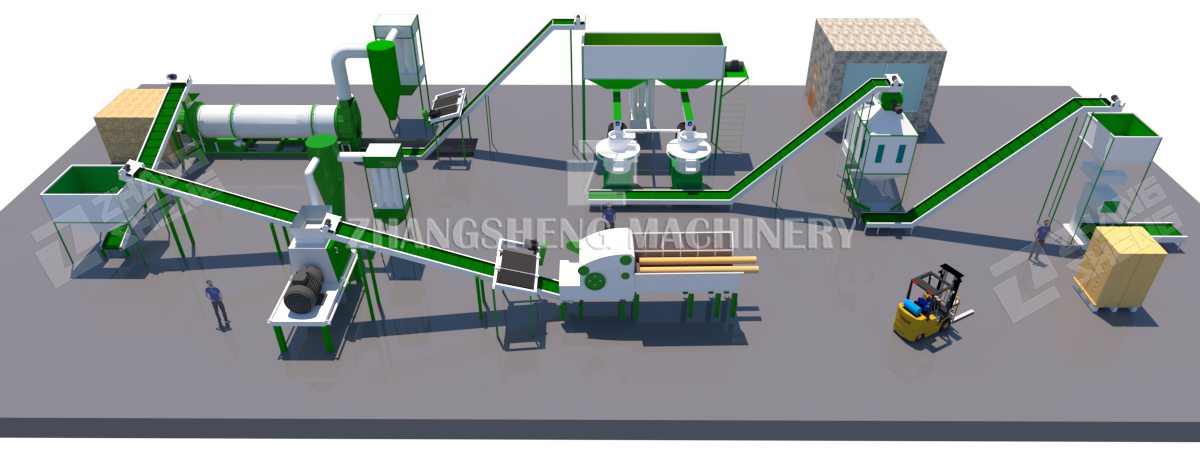

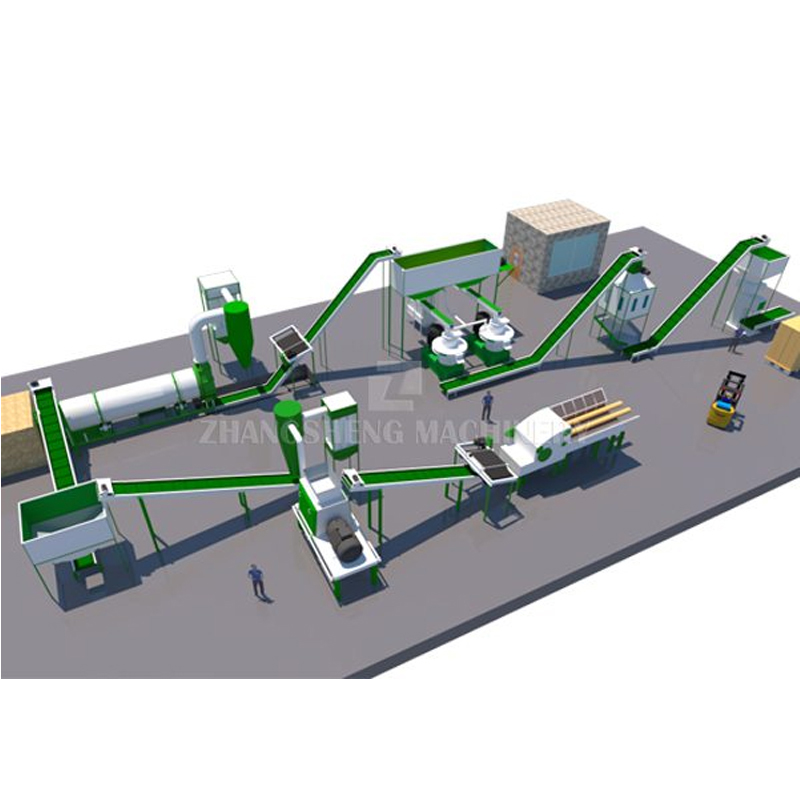

The waste wood pellet production line includes crushing, drying, pelletizing, cooling, packaging and other processes. Realize the processing of waste wood into biomass pellets.

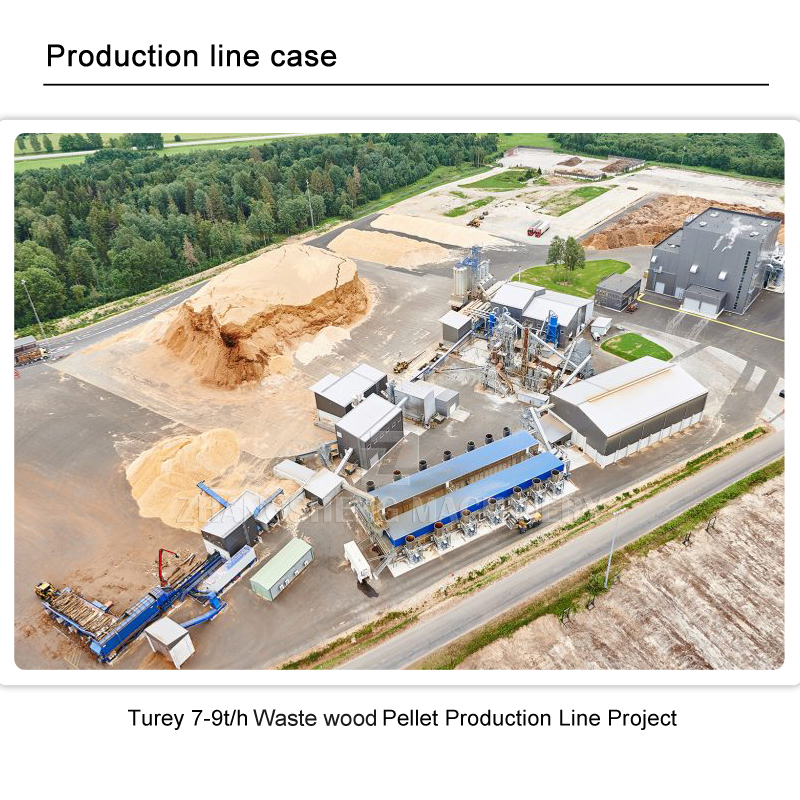

We can provide production lines with an output of 1-10 tons per hour. It can process all kinds of waste wood, such as wood processing plant scraps, wooden pallets, building templates, waste furniture, sawdust, branches, tree trunks, building templates, etc.

Wood pellets have a high calorific value and are mostly used in large power plants, medium-sized district heating systems and small residential heating. Wide range of needs and high applicability.

Wood pellets are small in size and low in transportation costs. The raw materials are renewable, and you can save about half your fuel bill compared to gasoline or natural gas. With more than 80% lower greenhouse gas emissions than coal, wood pellets are one of the most effective ways to meet renewable energy and carbon reduction goals.

From 2010 to 2025, the demand for industrial wood pellets will grow at an average rate of about 2.3 million tons per year. Global industrial pellet demand grew by 18.4% between 2020 and 2021, while production grew by only 8.4%. The EU region and the UK, in particular, often experience pellet shortages amid high energy costs. Therefore, the wood pellet production line is a promising and lucrative project.

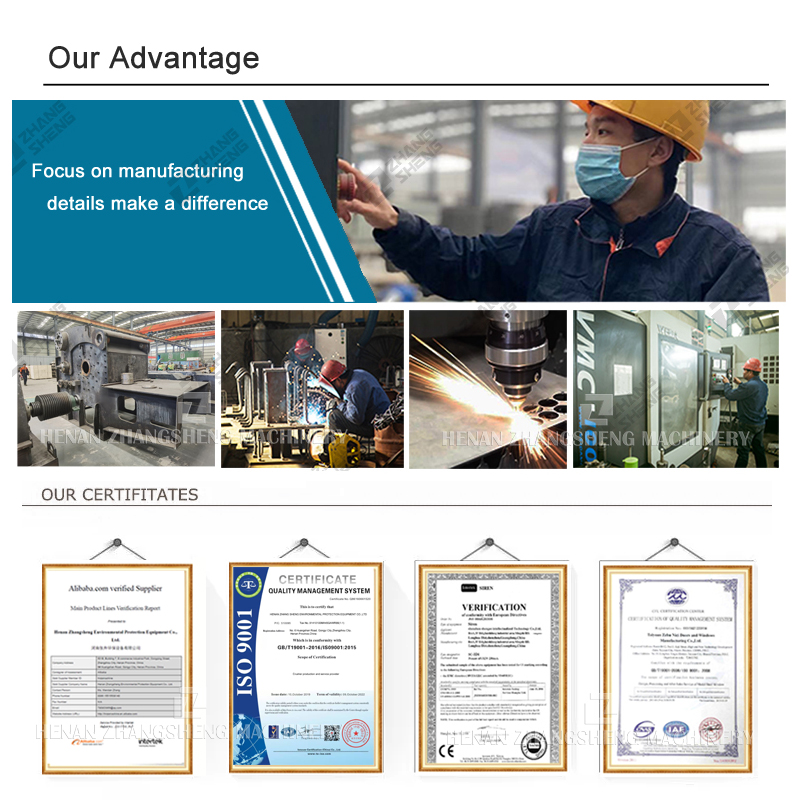

1. The cleanliness of the pellet production line we manufacture can reach 98%, which effectively ensures the cleanliness of the workshop environment.

2. As an equipment manufacturer, we can also provide tailor-made solutions according to customer requirements.

3. We have professional knowledge and rich experience to help customers optimize factory operations and help them improve economic efficiency.

4. We fully understand the industry trends and work with partners to build a future-oriented biomass wood pellet plant.

1. The primary crushing section mainly cuts tree trunks and logs with a diameter of less than 50cm into wood chips less than 20mm.

2. The hammer mill crush the wood chips with a diameter of less than 20mm into sawdust with a diameter of less than 8mm.

3. The drying section reduces the moisture content of wood sawdust from 20%-60% to 12-18%. Ensure that the finished product is well formed, of good quality and good market.

4. The pellet mill can make dry wood chips into pellets, and the output of a single machine can reach 3t/h.

5. The cooling system cools thepelletes from 70-90 ℃ to room temperature, and the pellet hardness will become stronger.

6. Put 10kg/25kg/100kg or 1 ton of qualified pellets into the packaging bag, and sew with a thermoplastic sealing machine to make the pellets dry and waterproof.

Note: We will customize different pellet production plans for you according to different sites, raw materials, output and budget. As a leading pellet machine manufacturer in China, Zhang Sheng has rich experience in pellet machine manufacturing and can build a successful pellet production line for you according to the actual situation.

We have 20 years experience in wood recycling industry.

Our product lines have been exported to more than 50 countries and won good reputation from them.

1. Are you a factory or a trading company?

We have our own factory. we have over 20 years of experience in the pellet line manufacturing. “Market our own products” reduces the cost of intermediate links. OEM available according to your raw materials and output.

2. Which raw materials can be made into biomass pellets? If any requirements?

Raw material can be wood waste, logs, tree branch, straw, stalk, bamboo, etc including fiber.

But the material for directly making wood pellets is sawdust with a diameter of no more than 8mm and moisture content of 12%-18%.

so if your material is not Sawdust and moisture is more than 20%, you need more machines, such as wood chipper, hammer mill and dryer etc

3. I know very little about pellet production line, how to choose the most suitable machine?

Do not worry. We have helped a lot of beginners. Just tell us your raw material, your capacity (t/h) and the size of the final pellet product, we will choose the machine for you according to your specific situation.

Product detail pictures:

Related Product Guide:

owing to excellent assistance, a variety of high quality products and solutions, aggressive costs and efficient delivery, we take pleasure in an excellent popularity amongst our customers. We are an energetic business with wide market for Factory Cheap Hot Disc Wood Chipper - waste wood pellet production line – Zhangsheng , The product will supply to all over the world, such as: Sudan, Muscat, Bhutan, We only supply quality items and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom merchandise etc that can according to customer's requirement.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.